Gorgon CO2 injection questions remain one year on

Chevron's ambitious injection of Gorgon CO2 shaped the $US54B LNG project and a year after starting up 2.5 years late its long-term performance remains to be proved.

Gorgon LNG’s controversial and late storage of CO2 underground started 12 months ago, but operator Chevron will not confirm if it is fully operational.

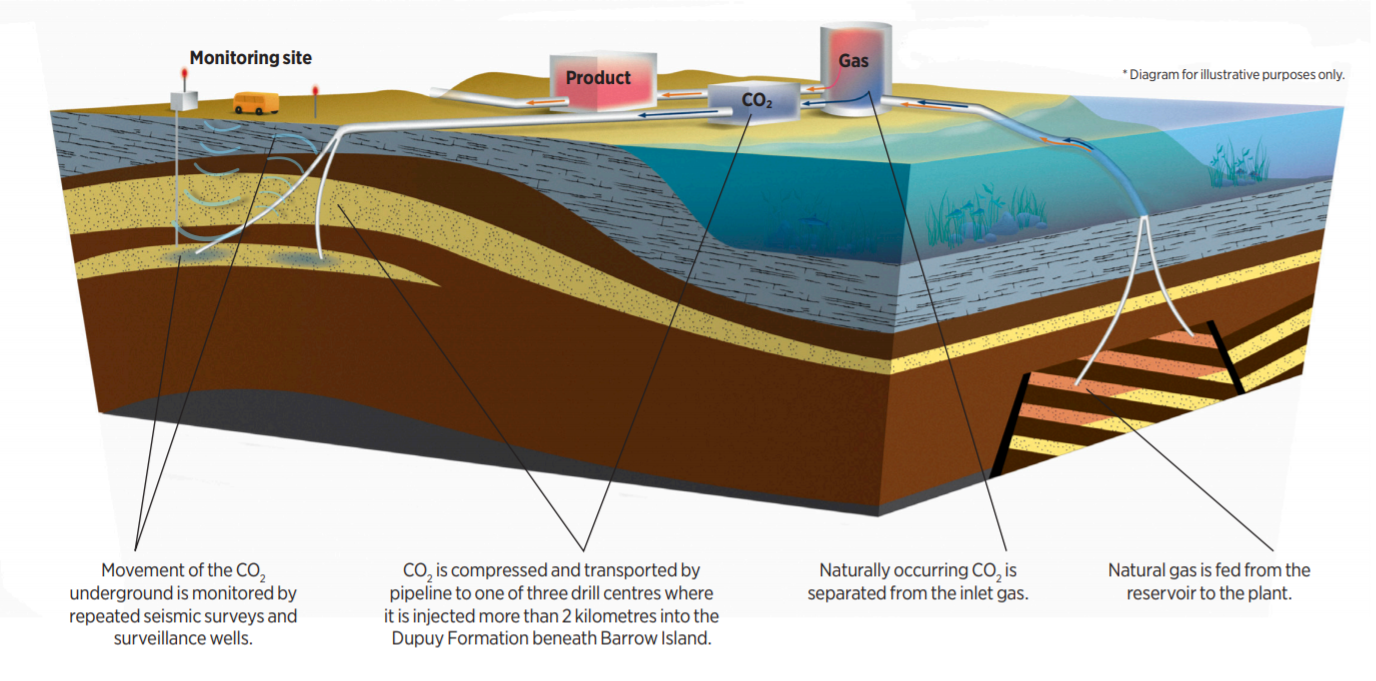

The first of three units that compresses CO2 from gas in the Gorgon reservoir and sends it to wells that go deep under Barrow Island started operating on 8 August 2019: two and a half years after production from the CO2-rich Gorgon field commenced.

In March Chevron Australia operations director Kory Judd said the system, designed to store up to four million tonnes of carbon dioxide a year, was then fully operational.

Gorgon must inject at least 80 per cent of the CO2 from the reservoirs that feed its $US54 billion plant

Chevron would not answer if the system was meeting this requirement in July before the planned shutdown of the second of Gorgon’s three LNG trains.

A Chevron spokesperson said the system’s performance would be made public in November when it must release a report.

Another unknown is whether Chevron and its partners, principally Shell and ExxonMobil, will suffer a penalty for the excess greenhouse gas emissions caused by the delayed start and slow ramp-up of CO2 injection.

In July, the State Government backed a recommendation from the WA Environmental Protection Authority that Gorgon was required to inject CO2 from the start of operations, not two years after that Chevron argued for.

However, Chevron will have to wait until at least July 2021, the end of the first five-year period that average injection is measured over, before the State Government reveals what action it will take.

Boiling Cold estimated that the emissions above the 80 per cent target could cost more than $80 million at the current price for Australian carbon credits.

World-leading ambition

In the 28 years from discovery in 1981 to project go-ahead in 2009 Gorgon gained the tag within the oil and gas industry of being deep, dirty, distant and dry.

The depth was 220m of water, the distance was 130km from the mainland, dry meant the gas had little valuable condensate, and the dirt was the 14 per cent of carbon dioxide in the gas from the Gorgon field, one of two that feeds the project.

In the end, reducing CO2 emissions shaped the whole project.

It resulted in construction on Barrow Island with limited land area, little infrastructure, strict environmental and quarantine conditions, and the need to transport almost everything in by sea.

However, Barrow Island had one advantage, a sandstone formation called the Dupuy, 2500m below the island, that could store CO2.

Gorgon was to emit 6.1 million tonnes of CO2 a year and inject a further 3.4 million tonnes a year under Barrow Island, according to Gorgon’s Greenhouse Gas Abatement Plan.

The total CO2 produced by Gorgon is greater than the 9 million tonnes emitted from Collie’s coal-fired power stations.

Injecting 80 per cent of the CO2 from the reservoirs will make Gorgon the third biggest CO2 storage project in the world.

The cost was estimated to be $2 billion in 2010 before the cost of the whole Gorgon project increased by 46 per cent and the injection system needed substantial modification. The Federal Government contributed $60 million.

Gorgon has a long-term target to store 95 per cent of the reservoir CO2, or almost four million tonnes a year.

Separating CO2 from the reservoir gas was required to avoid CO2 causing corrosion and freezing into solid dry ice in the LNG plant, so was not an additional cost.

Gorgon will not separate and store the CO2 from the turbines that generate power and liquefy the gas. The only two projects that store CO2 from combustion, in Canada and the US, are on a smaller scale than Gorgon. They recoup the expense by injecting the CO2 into depleted oil reservoirs to increase production.

Only five of the 19 carbon storage projects operating in 2019, including Gorgon, do not use the CO2 to increase oil production.

Nothing simple about burying CO2

The first step in storing the CO2 underground it is to compress it to a pressure sufficient to force it down the injection wells and then deep into the sandstone and siltstone of the Dupuy Formation.

When compressed, the CO2 is neither a true gas or liquid: it is kept at a so-called super-critical phase by controlling the temperature and pressure of the gas.

The super-critical CO2 is easier to drive into the Dupuy because it flows like gas but requires less storage volume as it is dense like liquid.

The 7km pipeline from the compressors at the LNG plant to the injection wells was at risk as CO2 mixed with water is highly corrosive.

The compressors were configured to ensure the water stayed entrapped in the CO2 flow and did not become so-called free water that would cause corrosion.

The alternatives for the designers had been to use expensive corrosion-resistant alloys or install additional equipment to remove almost all water from the stream of CO2 before entered the pipeline.

Gorgon’s 2017 environmental performance report revealed that when tested in March 2017 the pipeline to the injection wells had leaky and corroded valves and under certain conditions water could condense in the pipeline and cause corrosion.

More than two years passed with all reservoir CO2 flowing to the atmosphere while units to dry the gas, that the initial design was meant to avoid, were installed.

There was some industry chatter that had revenue been affected the work would likely have taken less time.

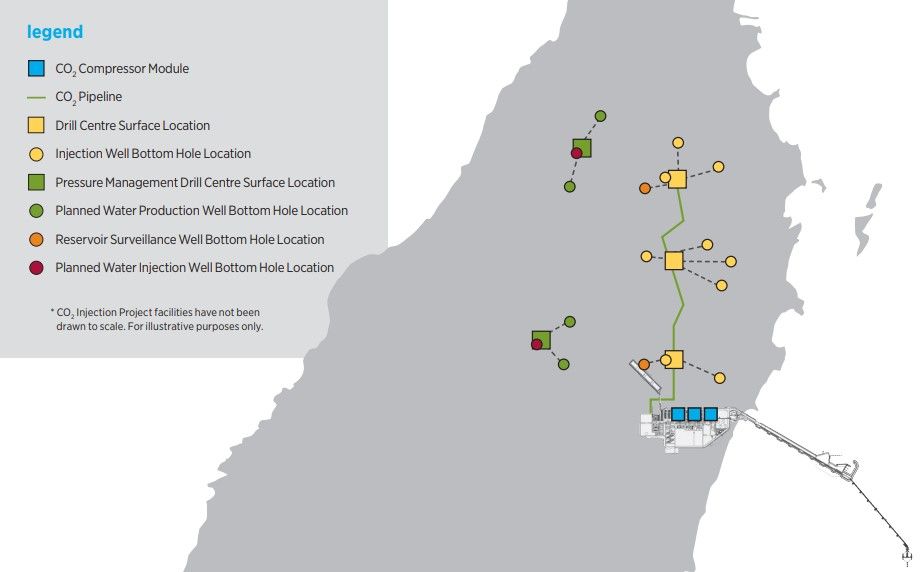

The pipeline delivers CO2 to nine wells drilled deep into Dupuy.

Up to nine more wells may be required later to control the gas pressure at the bottom of the wells.

High pressure could fracture the formation and disturb the planned flow of over seven tonnes of CO2 a minute into the sandstone.

Once underground the CO2 sticks to the surface of rock grains or dissolves into the water between them.

As more CO2 is stored underground, the pressure in the Dupuy Formation could increase and reduce the flow through each injection well.

This pressure increase is managed by extracting water from one side of the Dupuy at the same CO2 is injected into the other.

Several kilometres west of the injection wells are four wells with electric submersible pumps that can lift over 12,000 tonnes of water a day to the surface. This water is then reinjected into a formation above the CO2.

Part of this story was originally published in the West Australian 26 September 2017 as “Gorgon’s next big challenge.” © Peter Milne

Main image: Workers at a CO2 injection facility on Barrow Island. Source: Chevron Australia Pty Ltd.