Westport bill may jump $1b to keep desalination plant working

Longer pipelines into Cockburn Sound must be built before port construction begins or 15 per cent of Perth's water supply will be lost.

Chevron's Gorgon should be a showpiece of carbon capture and storage but five years after first LNG it is still not working properly and has another five-month extension from the regulator.

Chevron’s $3.1 billion carbon storage system will be throttled back for another five months after the US-major again failed to bring a vital system to manage underground pressure fully into operation.

Chevron was allowed to build the massive $54 billion ($72 billion) Gorgon LNG project on the Barrow Island nature reserve so it could bury CO2 under the island.

Although Gorgon has now produced LNG for more than five years, all components of the CO2 injection system are yet to work simultaneously. Boiling Cold estimated that up to mid-2020, seven million tonnes of CO2 was vented to the atmosphere that should have been buried.

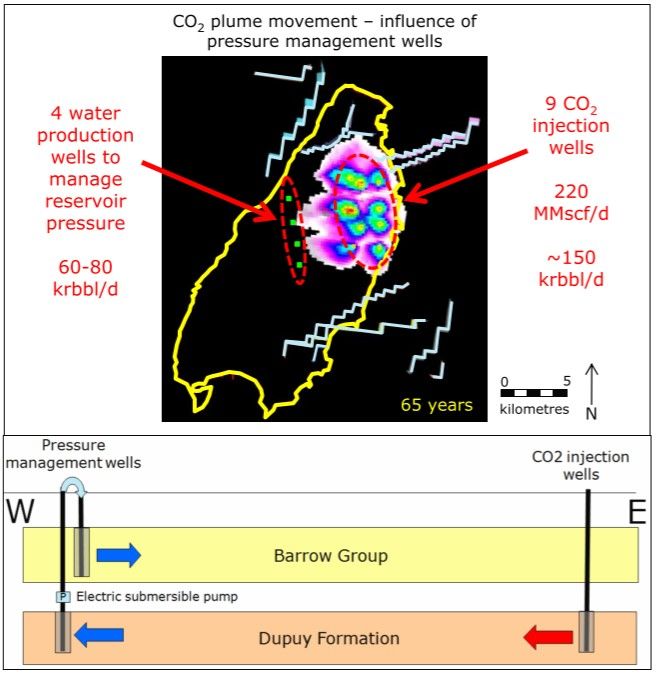

The plan is that CO2 is pumped into a formation 2000m underground displacing water contained in crevices of the rock. To stop the pressure in the formation from rising, water is pumped to the surface a few kilometres from the CO2 injection wells and then reinjected into a different underground structure.

The water wells, known as the pressure management system, were tested in early 2019. Unexpected amounts of sand in the water coming to the surface clogged the water injection wells that were to dispose of the water underground.

The WA Department of Mines, Industry Regulation and Safety allowed Chevron to begin injecting CO2 while the pressure management system was fixed and has since granted four extensions of time.

From December 2020, DMIRS allowed a further six months of injection, but this time restricted it to about one-third of design capacity. The regulator considered there was a low risk that the system’s long-term performance would be damaged without control of pressure in the formation.

In early 2021 Chevron reported to DMIRS that it anticipated the system would be operational by mid-2021 but again has missed a deadline.

DMIRS resource and environmental compliance director Karen Caple said the regulator granted Chevron another extension to 30 November 2021 as it had made significant progress in remedying the issues.

“Additional time is needed to test the system operating at full capacity and to ensure it is operating in a safe, stable and functional manner,” Caple said.

The system is still restricted to one-third capacity, but Chevron is now allowed to increase injection to two-thirds capacity once it can operate all the pressure management wells at the same time.

At full capacity, the system can store up to four million tonnes of CO2 a year.

Caple said once the system is fully operational and verified as safe, stable and functioning, DMIRS would review the need for restricting injection rates.

A Chevron spokesperson said while the injection of greenhouse gas emissions was reduced it continued to work with DMIRS.

“Like any pioneering endeavour, the system, which has injected more than 4.8 million tonnes of greenhouse gas emissions since August 2019, has presented some challenges,” the Chevron spokesperson said.

“The system has already resulted in a significant reduction in emissions for Gorgon, with Clean Energy Regulator data released in February 2021 showing a 30% reduction in Gorgon emissions over the last reporting period.”

The Chevron spokesperson said an upgrade to the filtration system for the sand was now complete and all pressure management wells had been operated separately.

The oil and gas industry uses the promise of carbon capture and storage to argue it does not have to curtail its production dramatically and urgently to limit global warming.

Either CCS can quickly be deployed on a vast scale at an acceptable cost, or oil and gas companies must soon face reserves write-downs, stranded assets and plummeting share prices.

Gorgon should be the showpiece of CCS technology as the world’s largest carbon storage project dedicated to reducing greenhouse gas emissions. Most CCS projects boost oil production with high-pressure CO2.

The failure of Gorgon is a public relations disaster for the industry that, even in Australia, mentions Gorgon CO2 injection as little as possible, and any discussion usually omits its troubled run.

Gorgon should be as easy as CCS gets.

The capture of CO2 from the reservoir gas is needed for all LNG plants so was not an additional cost at Gorgon. In addition, the injection site was only a few kilometres away; the geology was known from decades of oil production; and the project backed by three oil and gas giants with prodigious technical and financial resources: Chevron, ExxonMobil and Shell.

Chevron struck trouble injecting CO2 under Barrow Island early on. The system was shut in mid-2017 due to leaking valves and corrosion concerns. It did not restart for two years.

Hydrocarbons have been reported in the water pumped to the surface. Caple said the amounts were relatively small and hydrocarbons are often naturally found in groundwater near oil and gas-bearing formations.

The reality is that carbon capture and storage is incredibly complex.

Chevron and its partners may soon bear a financial cost for the system’s underperformance. The first five-year period over which the WA Government measures if Gorgon has injected the required 80 per cent of CO2 produced from its offshore reservoirs ends in July.

The proportion of reservoir CO2 injected is much less 80 per cent and would have been worse except for other technical issues at Gorgon that have cut production.

For almost all of the past 14 months, one of the three LNG trains has been shut down to repair cracks in propane-filled pressure vessels called kettles.

The shutdowns were ordered by DMIRS after it learnt of the problem when the story was broken by Boiling Cold and The West Australian.

Boiling Cold asked DMIRS if the root cause of the problems with the kettles had been identified.

DMIRS director of dangerous goods and petroleum safety Steve Emery said the regulator was satisfied Chevron’s had identified the cause of the defects and addressed any risks associated with these defects.

“DMIRS’ officers continue to conduct their routine inspections and audits of the Gorgon plant,” Emery said.

In May, four workers on a train shutdown were drenched in chemicals containing mercury. A Worksafe spokesperson said tests afterwards showed none of the workers’ exposures were above the guidance values for biological mercury.

“The workers involved may require further testing of their mercury levels to confirm that this continues to be the case,” the Worksafe spokesperson said.

Update July 2, 2021, 11:15AM. Chevron comment on the filtration system and operation of the wells added.

Main image: Chevron sign at its Perth headquarters. Source: Peter Milne

All the info and a bit of comment on WA energy and climate every Friday