Five reasons Australia's green hydrogen dream has foundered

Several big green hydrogen projects have been shelved. An expert explains why Australia’s sky-high ambition for the industry is struggling to reach fruition.

Green steel made with renewable hydrogen could produce 25,000 Australian jobs but the Pilbara's iron ore would be shipped east to avoid high labour costs.

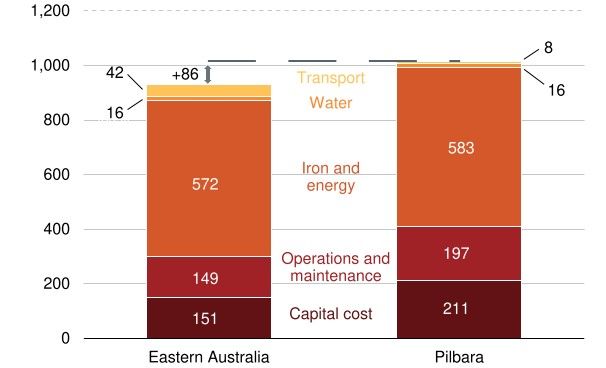

High labour costs in the Pilbara make the sun-drenched global iron ore powerhouse the wrong place in Australia for steel mills fired by green hydrogen, according to a report.

Australia could create tens of thousands of jobs in a competitive green steel export industry by using hydrogen produced with renewable energy to replace coal in the steelmaking process, a Grattan Institute report has concluded.

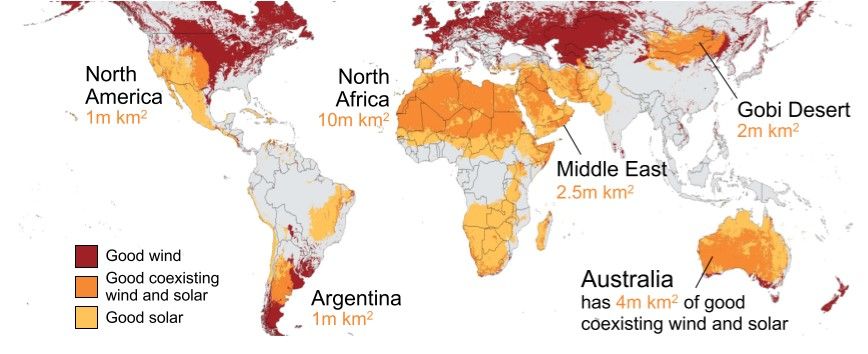

Vast resources of solar and wind energy could allow Australia to export green steel to countries such as Japan and Indonesia for less than those countries could make their own with imported iron ore and hydrogen.

The twin supports for Australia’s advantage are that it has the climate and space to generate vast quantities of renewable electricity for hydrogen production and that hydrogen is difficult and expensive to export.

The report concluded that other ways to effectively export renewable energy – biofuels, green hydrogen and ammonia and subsea power cables – would produce less Australian jobs than steel making.

Australia mines 38% of the world’s iron ore and 18% of its metallurgical coal, yet with those two main ingredients for steel produces just 0.3% of the world’s steel output.

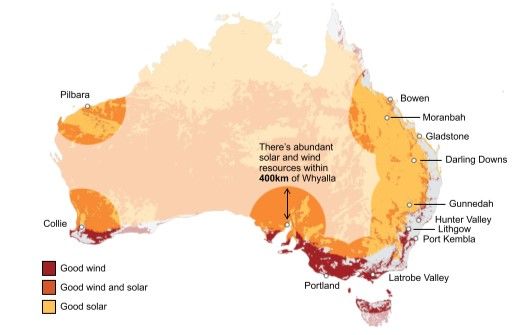

Despite having iron ore, wind and solar resources in abundance labour costs in the Pilbara make it too expensive to host a steel mill, according to Grattan. The need to build cyclone-proof infrastructure adds further costs.

“It would be cheaper to take the iron ore to the large pool of workers in central Queensland or the Hunter Valley than to try to attract workers from the south or east to the Pilbara,” the report said.

The report sees Australia as “stuck in a climate conundrum.”

“Political leaders need to balance the national interest – which requires strong global action on climate change – with the legitimate interests of regional communities and workers in carbon-intensive industries.”

The potential for tens of thousands of green steel jobs in the coal-producing regions of central Queensland and New South Wales’s Hunter Valley is a way to solve that problem.

The Pilbara could be a competitive location to produce direct reduced iron, an intermediate product in steel production, as it is less labour-intensive than steelmaking.

Governments must act now for Australia to seize the green steel opportunity, the report urged.

A “steel flagship project” using the direct reduction process could build steelmaking skills initially using mainly gas as a fuel with increasing amounts of renewable hydrogen over time.

If Australia can capture seven per cent of the world’s steel market with a new greener product the prize is 25,000 manufacturing jobs, the report concluded.

Main Picture: iron ore at Cape Lambert. Source: Rio

All the info and a bit of comment on WA energy and climate every Friday